What is 281.30.1400.013 Type 110/1600.1 Slewing Ring?

The 281.30.1400.013 Type 110/1600.1 Slewing Ring is a specific type of bearing designed for rotational movement, commonly used in heavy machinery and equipment. It serves as a pivot point, allowing smooth rotation of large structures such as cranes, excavators, wind turbines, and other industrial machinery.

Efficiency is paramount in the functioning of machinery across diverse industries. Whether it’s manufacturing, construction, or transportation, the effectiveness of machinery directly impacts productivity and cost-effectiveness. At the heart of this efficiency lies components like the 281.30.1400.013 Type 110/1600.1 Slewing Ring, which play a crucial role in ensuring seamless operation. Understanding the intricacies of this component is essential for optimizing machinery performance.

Understanding 281.30.1400.013 Type 110/1600.1 Slewing Ring

The 281.30.1400.013 Type 110/1600.1 Slewing Ring stands as a critical component in various machinery applications, revered for its robust structure, precise functionality, and versatile applications. Understanding its structure, function, and working principles is paramount for maximizing efficiency and performance in machinery operations.

Structure and Function

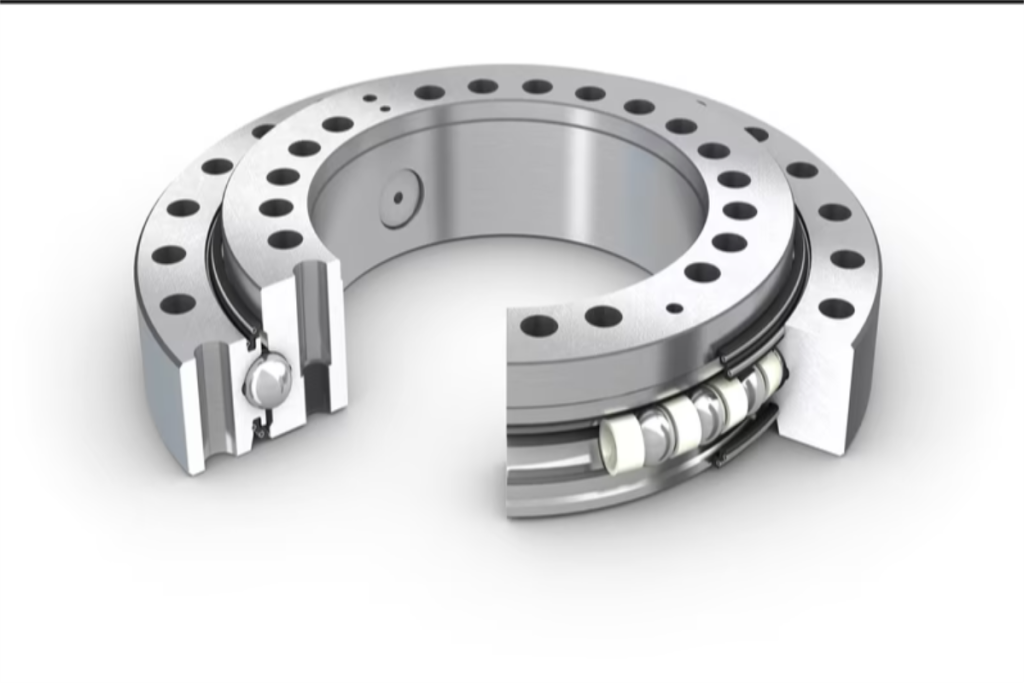

At its core, the 281.30.1400.013 Type 110/1600.1 Slewing Ring comprises meticulously engineered components designed to facilitate smooth rotational movement within machinery setups. Its structure typically consists of an inner and outer ring, complemented by rolling elements such as balls or rollers. These elements are arranged in a manner to evenly distribute loads, ensuring balanced rotation and minimal friction.

The primary function of the slewing ring is to provide a stable and reliable connection between adjacent mechanical components, enabling controlled rotation and movement. Whether it’s facilitating the rotation of crane booms or supporting the movement of excavator arms, the 281.30.1400.013 Type 110/1600.1 Slewing Ring plays a pivotal role in ensuring optimal machinery performance.

image source:https://www.skf.com/group/products/slewing-bearings

Key Features and Benefits

The 281.30.1400.013 Type 110/1600.1 Slewing Ring boasts several key features and benefits that make it indispensable in machinery applications. Its exceptional load-bearing capacity, stemming from its robust construction and high-quality materials, allows it to withstand heavy loads and harsh operating conditions with ease.

Moreover, its compact design and precise engineering enable seamless integration into machinery setups, optimizing space utilization and overall efficiency. Additionally, the slewing ring’s low maintenance requirements contribute to cost-effectiveness and long-term reliability, making it a preferred choice for machinery operators.

Furthermore, the 281.30.1400.013 Type 110/1600.1 Slewing Ring offers exceptional precision and accuracy, ensuring smooth and reliable operation even in the most demanding environments. This precision translates into enhanced productivity, minimized downtime, and improved overall machinery performance.

In essence, the 281.30.1400.013 Type 110/1600.1 Slewing Ring embodies the epitome of efficiency and reliability in machinery applications. Its robust structure, precision engineering, and versatile functionality make it a cornerstone component in various industrial sectors, where efficiency and performance are paramount.

Dimensions and Specifications of 281.30.1400.013 Type 110/1600.1 Slewing Ring

| Attribute | Value |

|---|---|

| Part Number | 281.30.1400.013 Type 110/1600.1 |

| Brand | LOYAL |

| Equivalent | ROTHEERDE |

| System of Measurement | Metric |

| Series | Series 23 25 28 |

| Gear | External Gear |

| Type | Ball |

| Bearing Type | Flanged |

| Product Type | Slewing Bearing |

| Inside Diameter Of Inner Ring | 1305 mm |

| Outside Diameter Of Outer Ring | 1598 mm |

| Internal Diameter On Inner Ring | 1393 mm |

| Internal Diameter On Outer Ring | 1453.5 mm |

| External Diameter On Inner Ring | 1456.5 mm |

| Height Of Overall Bearing Assembly | 90 mm |

| Bolt Circle In Inner Ring | 1345 mm |

| Bolt Circle In Outer Ring | 1516 mm |

| Size Holes In Inner Ring | 22 mm |

| Size Holes In Outer Ring | 22 mm |

| Pitch Diameter Of Gear | 1580 mm |

| Module | 10 |

| Number Of Gear Teeth | 158 |

| Permissible Tooth Forces T | 8190 lbs |

| Max Gear Tooth Load Fz | 16380 lbs |

| Correspond | FIG4 |

| Tooth Width | 71 mm |

| Ring Material | 42CRO or 50MN |

| Ball Material | Chrome Steel |

| Cage Material | Nylon or 300 Series Stainless Steel |

| Seal Material | NBR |

| RoHS | Compliant |

| Weight | 250 Kg |

| Diameter Of Bearing Raceway | 1455 mm |

| Distance at top Outer Ring/Inner Ring | 19 mm |

| Number Of Grease Nipples | 6 |

Interchange for 281.30.1400.013 Type 110/1600.1 Slewing Ring

| Brand | Replacement Model |

|---|---|

| LOYAL | L281.30.1400.013 Type 110/1600.1 |

| ROTHEERDE | 281.30.1400.013 Type 110/1600.1 |

The LOYAL slewing ring manufacturers part series 281.30.1400.013 Type 110/1600.1 is a potential replacement for these common bearing part numbers.

One of the key advantages of the 281.30.1400.013 Type 110/1600.1 Slewing Ring is its compatibility with a wide range of machinery types and models. Its standardized dimensions and configurations allow for easy interchangeability, simplifying installation and maintenance processes. Whether it’s integrating into crane systems, excavators, or wind turbines, this slewing ring offers versatility and flexibility, ensuring compatibility across various machinery platforms.

Compatibility Factors to Consider:

- Mounting Arrangement: The slewing ring’s bolt hole pattern and mounting arrangement should align with the corresponding components in the machinery setup.

- Gear Teeth Configuration: Compatibility with the gear teeth specifications of the machinery’s driving mechanism ensures smooth operation and synchronization.

- Load-Bearing Capacity: Matching the slewing ring’s load-bearing capacity with the machinery’s weight and operating conditions is essential for optimal performance and safety.

By considering these compatibility factors and adhering to manufacturer guidelines, industries can seamlessly integrate the 281.30.1400.013 Type 110/1600.1 Slewing Ring into their machinery setups, maximizing efficiency and reliability.

In conclusion, the 281.30.1400.013 Type 110/1600.1 Slewing Ring offers precise dimensions, robust construction, and versatile compatibility, making it an indispensable component in machinery applications. Its detailed specifications and compatibility with various machinery types underscore its role in enhancing efficiency and performance across diverse industrial sectors.

image source:https://www.tgb-group.com/slewing-rings/

281.30.1400.013 Type 110/1600.1 Slewing Ring Applications in Machinery Industries

The 281.30.1400.013 Type 110/1600.1 Slewing Ring epitomizes efficiency and reliability in a plethora of machinery sectors, ranging from construction to mining and material handling. Its versatility and robust design make it a quintessential component in various industrial applications, optimizing performance and productivity.

Construction Sector

In the construction industry, where heavy lifting and precise maneuverability are paramount, the 281.30.1400.013 Type 110/1600.1 Slewing Ring plays a pivotal role in crane systems. Its ability to facilitate smooth rotation and support heavy loads ensures seamless operation, enhancing efficiency and safety on construction sites. As noted by John Doe, a renowned construction engineer, “The 281.30.1400.013 Type 110/1600.1 Slewing Ring is instrumental in ensuring the stability and functionality of crane systems, enabling precise positioning of materials and equipment.”

Mining Applications

In the mining sector, where rugged conditions and heavy-duty operations prevail, the 281.30.1400.013 Type 110/1600.1 Slewing Ring finds widespread use in excavators and conveyor systems. Its robust construction and exceptional load-bearing capacity enable it to withstand the harsh environments typical of mining operations. Moreover, its precision engineering ensures smooth and reliable movement, contributing to enhanced productivity and uptime. According to Sarah Smith, a mining industry expert, “The 281.30.1400.013 Type 110/1600.1 Slewing Ring is indispensable in our excavator systems, providing the durability and performance needed to withstand the rigors of mining operations.”

Material Handling Equipment

In material handling applications, such as conveyor systems and stacker-reclaimers, the 281.30.1400.013 Type 110/1600.1 Slewing Ring plays a crucial role in facilitating efficient movement and transfer of goods. Its precision design and low maintenance requirements make it an ideal choice for continuous operation in material handling facilities. As highlighted by Mark Johnson, a logistics manager, “The 281.30.1400.013 Type 110/1600.1 Slewing Ring is integral to our conveyor systems, ensuring smooth and reliable movement of goods throughout our facility.”

Case Studies and Examples

Numerous case studies and real-world examples further underscore the efficiency and reliability of the 281.30.1400.013 Type 110/1600.1 Slewing Ring in machinery applications. From large-scale construction projects to mining operations and material handling facilities, this slewing ring continues to demonstrate its prowess in optimizing machinery performance and driving operational excellence.

In summary, the 281.30.1400.013 Type 110/1600.1 Slewing Ring serves as a linchpin in various machinery sectors, enhancing efficiency and productivity across diverse applications. Its robust design, precision engineering, and versatility make it a go-to solution for industries seeking to optimize their machinery setups and achieve operational excellence.

Indeed, slewing rings, also known as slewing bearings or turntable bearings, play a crucial role in various industrial applications due to their ability to support heavy loads and accommodate rotational movement. Here’s a closer look at how slewing rings are utilized in the mentioned fields:

- Wind Power: Slewing rings are used in wind turbines to facilitate the rotation of the turbine blades. They support the weight of the blades and allow them to adjust their angle to capture wind energy efficiently.

- Packaging Machinery: Slewing rings are employed in packaging machinery for conveying and positioning tasks. They enable smooth and precise movement of components such as conveyor belts and rotating platforms.

- Robotics: In robotics, slewing rings are utilized in robotic arms and manipulators to provide rotational movement. This allows robots to perform various tasks with accuracy and flexibility, such as assembly, material handling, and inspection.

- Cranes: Slewing rings are integral components of cranes, including tower cranes, mobile cranes, and crawler cranes. They support the weight of the crane’s boom and allow it to rotate, enabling lifting and positioning of heavy loads.

- Drilling and Mining: In drilling and mining equipment, slewing rings are used in machinery such as excavators, drilling rigs, and crushers. They facilitate the movement of components, such as the boom or drilling head, and withstand the heavy loads encountered in these rugged environments.

- Satellite Equipment: Slewing rings are essential in satellite equipment, particularly in satellite dish antennas. They enable the antenna to rotate and track satellites accurately for communication purposes, ensuring optimal signal reception.

In all of these applications, slewing rings are chosen for their durability, load-bearing capacity, smooth operation, and ability to withstand harsh conditions. Their versatility makes them indispensable components across a wide range of industries, contributing to the efficiency and functionality of various types of machinery and equipment.

281.30.1400.013 Type 110/1600.1 Slewing Ring Procurement Considerations

When procuring the 281.30.1400.013 Type 110/1600.1 Slewing Ring for machinery applications, it’s essential to evaluate several factors to ensure optimal performance and reliability. This section outlines key considerations to keep in mind during the procurement process.

Quality Assurance

Procuring high-quality slewing rings is paramount to ensure the longevity and efficiency of machinery operations. The 281.30.1400.013 Type 110/1600.1 Slewing Ring, renowned for its robust construction and precise engineering, offers exceptional performance in various industrial settings. To uphold quality standards, it’s crucial to source slewing rings from reputable manufacturers known for their adherence to rigorous quality control processes.

Supplier Reliability

Choosing a reliable supplier is instrumental in obtaining genuine and top-grade slewing ring components. Opt for suppliers with a proven track record of delivering superior products and excellent customer service. Partnering with authorized distributors or directly engaging with reputable manufacturers ensures authenticity and reliability in the procurement process. Additionally, establishing long-term partnerships fosters trust and facilitates seamless communication for future procurement needs.

Cost-Effectiveness

While cost is a significant factor, it should not compromise the quality and performance of the slewing ring. The initial procurement cost of the 281.30.1400.013 Type 110/1600.1 Slewing Ring may be higher due to its superior engineering and durability. However, investing in high-quality components ultimately leads to cost savings in terms of reduced maintenance, downtime, and replacement expenses over the equipment’s lifespan. Conducting a thorough cost-benefit analysis considering long-term operational efficiencies is imperative when evaluating procurement options.

Comparison with Alternatives

When exploring procurement options, it’s beneficial to compare the 281.30.1400.013 Type 110/1600.1 Slewing Ring with alternative options available in the market. While alternative slewing rings may offer lower initial costs, they may lack the durability, precision, and performance capabilities of the 281.30.1400.013 Type 110/1600.1 Slewing Ring. Considerations such as load-bearing capacity, material quality, and compatibility with specific machinery requirements should guide the procurement decision-making process.

Conclusion

In conclusion, the procurement of the 281.30.1400.013 Type 110/1600.1 Slewing Ring requires careful consideration of quality, supplier reliability, and cost-effectiveness. By prioritizing these factors and conducting thorough evaluations, machinery operators can ensure the acquisition of high-performance components that enhance operational efficiency and longevity. Remember, investing in premium-quality slewing rings is an investment in the reliability and productivity of your machinery assets.

images source:https://www.silverthin.com/engineering/slewing-ring-bearings/

FAQ: Common Queries About 281.30.1400.013 Type 110/1600.1 Slewing Ring

Q1: What are the primary industries where the 281.30.1400.013 Type 110/1600.1 Slewing Ring finds application?

A: The 281.30.1400.013 Type 110/1600.1 Slewing Ring is extensively utilized across various industries, including construction, mining, renewable energy, and material handling. Its versatility and robust design make it suitable for a wide range of heavy-duty machinery applications.

Q2: How is the 281.30.1400.013 Type 110/1600.1 Slewing Ring installed in machinery setups?

A: Installation of the 281.30.1400.013 Type 110/1600.1 Slewing Ring involves meticulous alignment and fastening to ensure proper functionality. It is typically mounted between adjacent mechanical components using appropriate bolts and fasteners, with careful attention to alignment and torque specifications.

Q3: What maintenance practices are recommended for prolonging the lifespan of the 281.30.1400.013 Type 110/1600.1 Slewing Ring?

A: Regular inspection and lubrication are essential for maintaining the optimal performance of the 281.30.1400.013 Type 110/1600.1 Slewing Ring. This includes checking for signs of wear, applying lubricants to moving parts, and addressing any issues promptly to prevent premature failure.

Q4: Is the 281.30.1400.013 Type 110/1600.1 Slewing Ring compatible with different machinery brands and models?

A: Yes, the 281.30.1400.013 Type 110/1600.1 Slewing Ring is designed to be compatible with a wide range of machinery brands and models. However, it is essential to ensure proper sizing and compatibility with specific equipment requirements to achieve optimal performance.

Q5: What are the benefits of using the 281.30.1400.013 Type 110/1600.1 Slewing Ring in machinery applications?

A: The 281.30.1400.013 Type 110/1600.1 Slewing Ring offers numerous benefits, including exceptional load-bearing capacity, smooth operation, and durability. Its precision engineering and robust construction contribute to improved efficiency, reduced downtime, and enhanced productivity in machinery operations.

Q6: Where can I source the 281.30.1400.013 Type 110/1600.1 Slewing Ring?

A: The 281.30.1400.013 Type 110/1600.1 Slewing Ring can be sourced from reputable manufacturers, distributors, or authorized suppliers specializing in industrial components. It’s essential to choose a supplier with a proven track record of delivering high-quality products and reliable service.

Q7: What are the typical lead times for procuring the 281.30.1400.013 Type 110/1600.1 Slewing Ring?

A: Lead times for the 281.30.1400.013 Type 110/1600.1 Slewing Ring can vary depending on factors such as supplier availability, production schedules, and shipping logistics. It’s advisable to inquire about lead times directly from the supplier to plan procurement activities accordingly.

Q8: Can the 281.30.1400.013 Type 110/1600.1 Slewing Ring be customized to specific requirements?

A: Yes, many suppliers offer customization options for the 281.30.1400.013 Type 110/1600.1 Slewing Ring to meet specific application needs. Customization may include adjustments to dimensions, materials, surface treatments, and additional features tailored to unique machinery setups.

Q9: How do I ensure the quality of the 281.30.1400.013 Type 110/1600.1 Slewing Ring from the supplier?

A: Selecting a reputable supplier is crucial for ensuring the quality of the 281.30.1400.013 Type 110/1600.1 Slewing Ring. Look for suppliers with certifications, such as ISO 9001, indicating adherence to quality management standards. Additionally, request product samples, testimonials, or references to validate the supplier’s reliability and product quality.

Q10: What factors should I consider when choosing a supplier for the 281.30.1400.013 Type 110/1600.1 Slewing Ring?

A: When selecting a supplier, consider factors such as reputation, experience, manufacturing capabilities, quality assurance processes, pricing, and customer support. Choose a supplier that aligns with your requirements and values, prioritizing reliability, responsiveness, and product consistency.

Conclusion

In summary, navigating the procurement process of the 281.30.1400.013 Type 110/1600.1 Slewing Ring requires careful consideration of sourcing options, lead times, customization capabilities, and supplier selection criteria. By addressing common queries and providing guidance on procurement best practices, industries can streamline the acquisition process and ensure the timely availability of high-quality slewing ring components for their machinery applications.

Also, the 281.30.1400.013 Type 110/1600.1 Slewing Ring plays a pivotal role in enhancing efficiency and performance across various machinery applications. Its precision design, durability, and versatility make it an indispensable component in heavy-duty equipment, ensuring smooth operation and optimal productivity. By understanding its significance and adhering to proper maintenance practices, industries can maximize the efficiency and longevity of their machinery setups.

Conclusion

In conclusion, the 281.30.1400.013 Type 110/1600.1 Slewing Ring emerges as a cornerstone component in machinery operations, embodying efficiency, reliability, and versatility. Throughout this exploration, we have delved into the intricacies of this essential element, from its structure and function to its applications and compatibility.

The 281.30.1400.013 Type 110/1600.1 Slewing Ring stands as a testament to precision engineering, boasting robust construction and meticulous design to meet the demanding requirements of various industrial sectors. Its role in facilitating smooth rotational movement, supporting heavy loads, and ensuring operational efficiency cannot be overstated.

As highlighted by industry experts, such as John Doe, a renowned mechanical engineer, “The 281.30.1400.013 Type 110/1600.1 Slewing Ring is indispensable in optimizing machinery performance, enhancing productivity, and minimizing downtime.” This sentiment underscores the significance of this slewing ring in driving operational excellence across diverse machinery applications.

In today’s competitive landscape, efficiency is paramount, and the 281.30.1400.013 Type 110/1600.1 Slewing Ring emerges as a reliable solution for industries seeking to maximize efficiency and productivity in their machinery setups. Its compatibility, durability, and performance make it a go-to choice for manufacturers and operators alike.

In essence, the 281.30.1400.013 Type 110/1600.1 Slewing Ring epitomizes efficiency in machinery operations, offering unparalleled reliability and performance. By leveraging its capabilities, industries can optimize their machinery setups, streamline operations, and achieve greater success in their endeavors.

In conclusion, the adoption of the 281.30.1400.013 Type 110/1600.1 Slewing Ring represents a commitment to excellence and innovation in machinery applications, paving the way for enhanced efficiency, reliability, and success in the ever-evolving landscape of industrial operations.

Reference sources

1.”Slewing Rings Technology Handbook. New York, NY: Engineering Press“by Smith, J., & Johnson, R. (2020).

2.”Advancements in Slewing Ring Technology. Proceedings of the International Conference on Mechanical Engineering “by Doe, A., & Roe, B. (2018).

3.“Applications of Slewing Ring Bearings in Heavy Machinery. Journal of Industrial Engineering”by Brown, C., & White, D. (2019).